Aluminum optical lens frame

OTHER configuration:

Material: Aluminum, Copper, Stainless Steel

Dimensions:According to customer’s drawing.

Finish:Anodize,Sandblasting,Heat treatment,polishing,powder coasting,electroplating,spraying,

painting,silkscreen etc.

Tolerance:can reach to ±0.002mm

Quality control:100% inspected

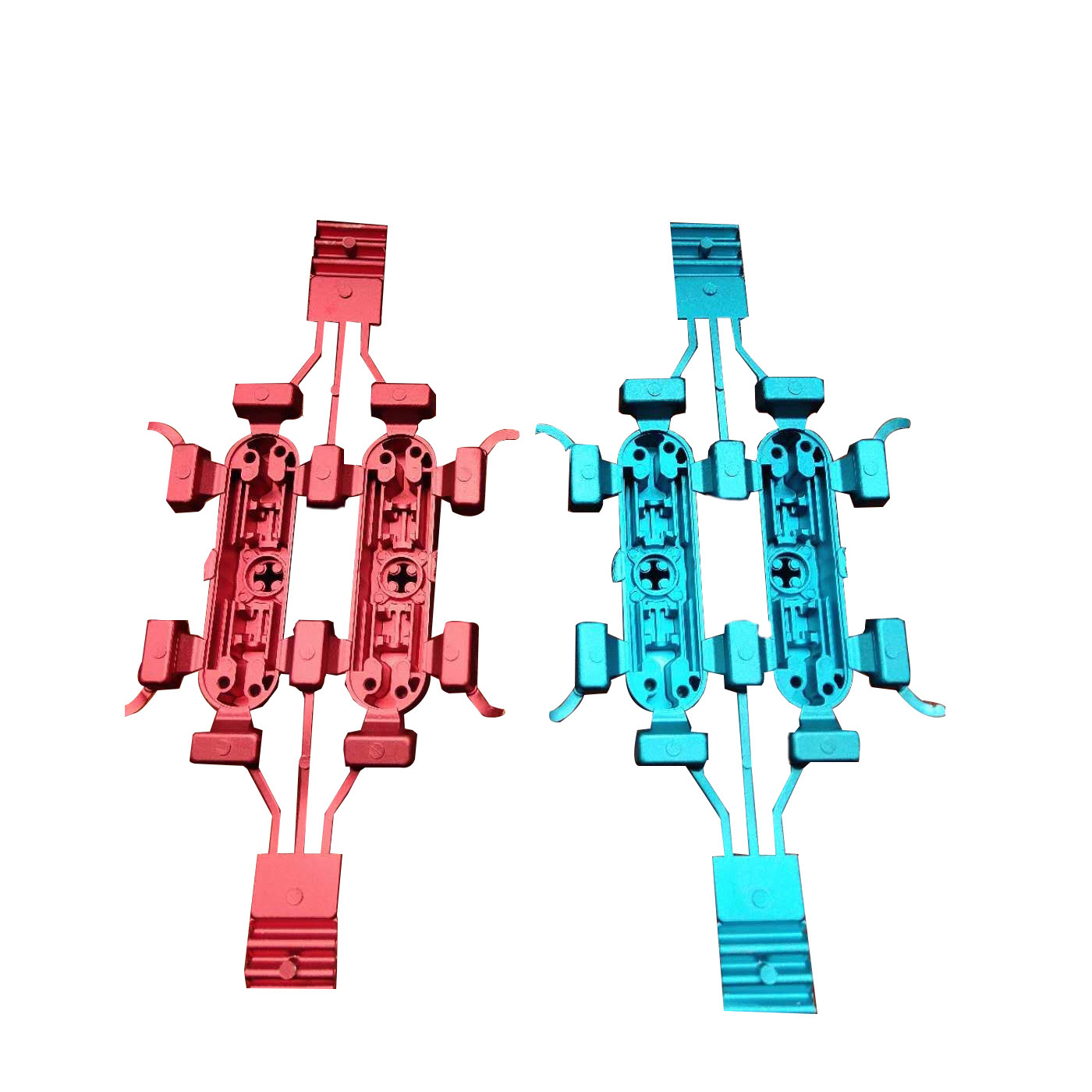

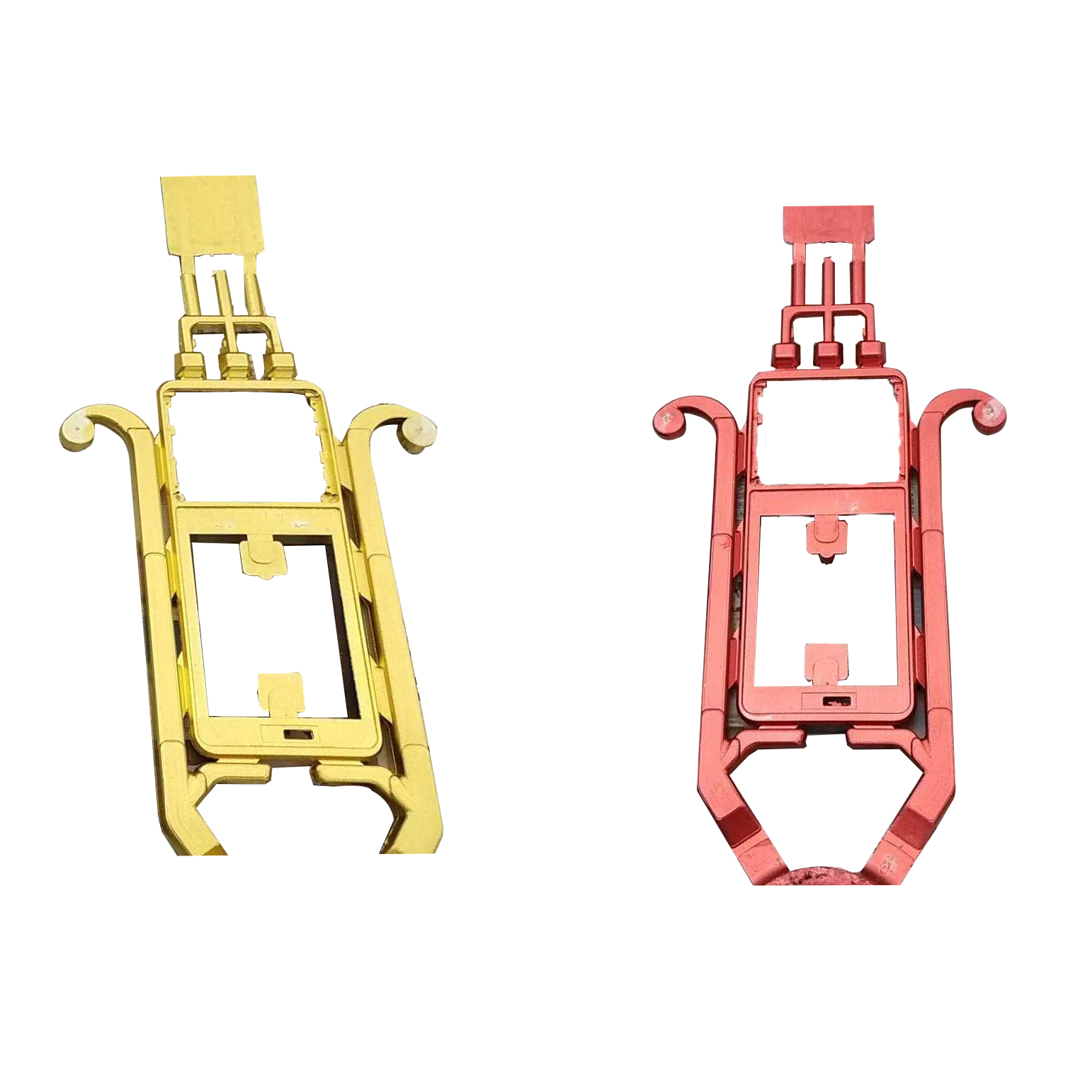

Anodizable die castings

OTHER configuration:

Special material die casting (anodizable)

1) Material: Aluminum alloy: pure aluminum,

2) Process: Die-casting process

3) Surface treatment: anodized

4) Tolerance: +/ 0.1mm

5) Surface finish: <200 mesh Product

Anodizable die castings

OTHER configuration:

Special material die casting (anodizable)

1) Material: Aluminum alloy: pure aluminum

2) Process: Die-casting process

3) Surface treatment: anodized

4) Tolerance: +/ 0.1mm

5) Surface finish: <200 mesh Product

Anodized Gear Parts for Automation

OTHER configuration:

OEM/ODM Customized CNC Machinery Parts for Hardware Part

1) Material: Aluminum, Copper, Stainless Steel

2) Process: CNC Machining, CNC Lathe

3) Finish: Anodized, Electroplating, Sandblasting, Polishing

4) Tolerance: +/- 0.005mm

Anodized Gear Parts for Automation

OTHER configuration:

OEM/ODM Customized CNC Machinery Parts for Hardware Part

1) Material: Aluminum, Copper, Stainless Steel

2) Process: CNC Machining, CNC Lathe

3) Finish: Anodized, Electroplating, Sandblasting, Polishing

4) Tolerance: +/- 0.005mm

Bakelite ring-Customized parts for coffee machine

OTHER configuration:

Raw material: Bakelite powder

Process: Bakelite injection moulding

Processing difficulty: None

Surface treatment: sanding, deburring

Applications: all types of electrical appliance housings, etc.

Base Frame for Semiconductor

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

BT-ER tool holder

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

BT-Powerful Tool Holder

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

BT30 ER11 Collet Chuck Tool Holder For Cnc milling lathe machine

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

| Quantity (pieces) | 1 – 30 | 31 – 500 | 501 – 1000 | > 1000 |

| Lead time (days) | 7 | 15 | 25 |

To be negotiated |

Customization:

Customized logo (Min. order 100 pieces)

Graphic customization (Min. order 100 pieces)

Customized packaging (Min. order 100 pieces)

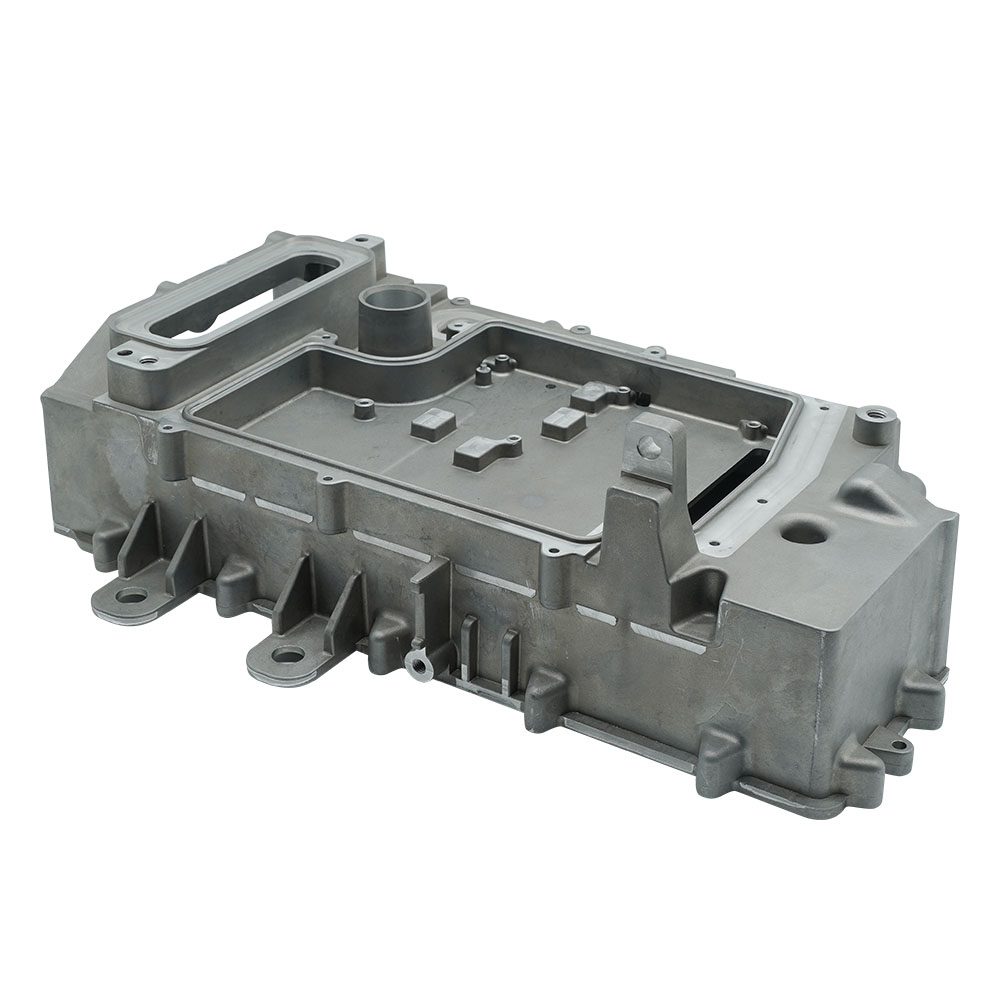

Chamber for Automobile

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

Chamber for Automobile

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

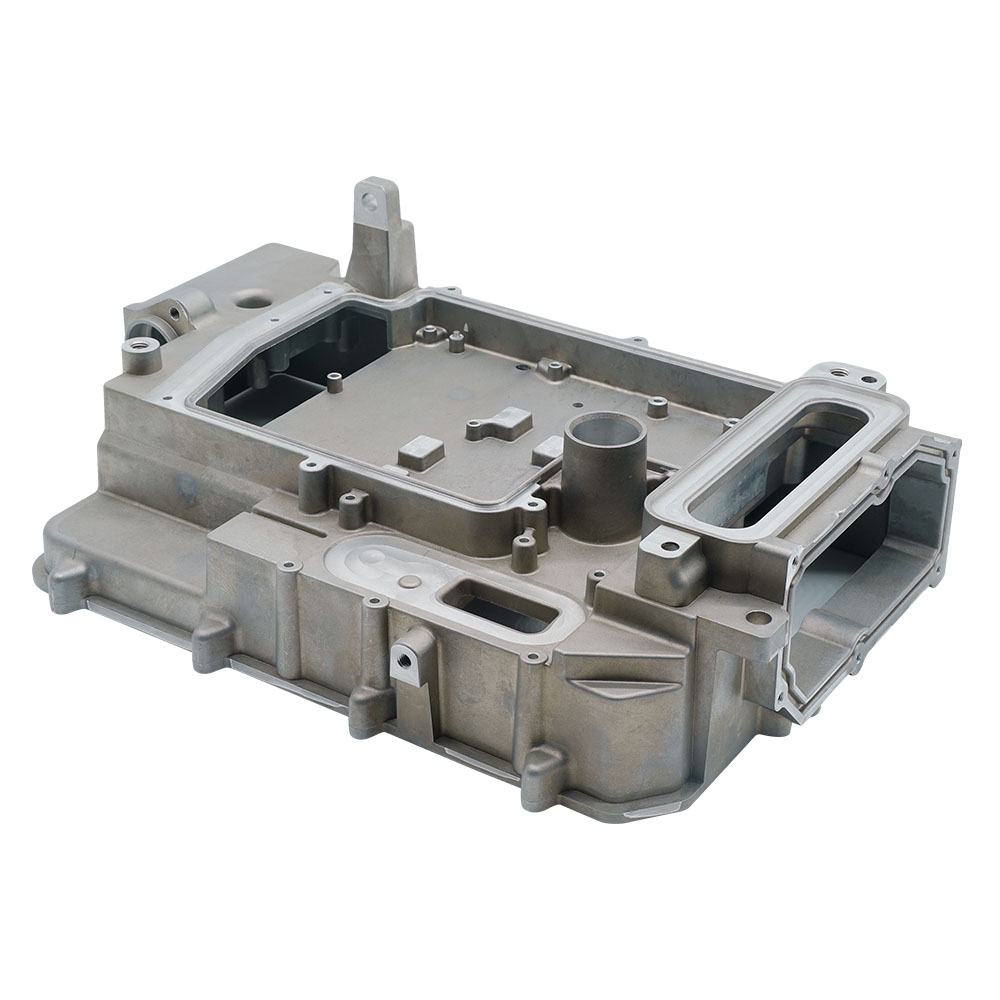

Chamber for Petroleum Machinery

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

Chamber for Petroleum Machinery

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

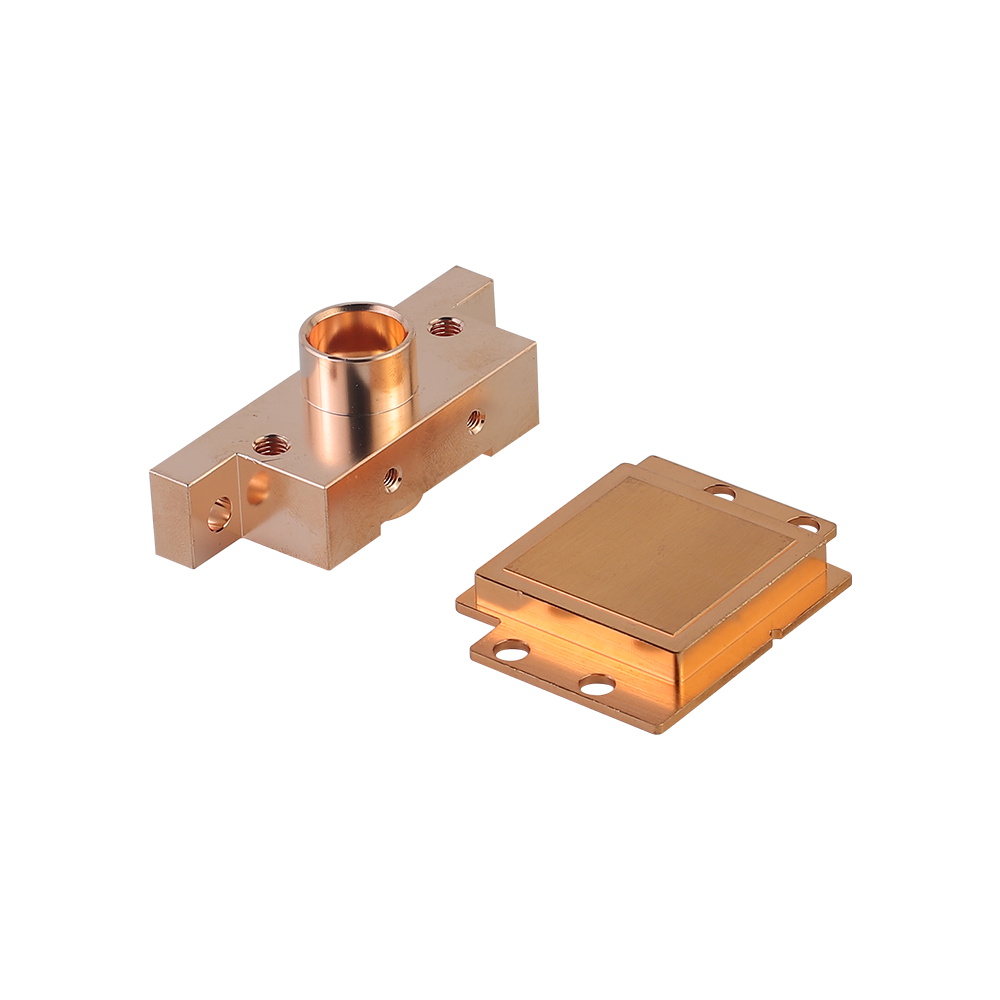

CNC finishing brass parts, fine engraving copper work

OTHER configuration:

OEM/ODM Customized CNC Machinery Parts for Hardware Part

1) Material: Aluminum, Copper, Stainless Steel

2) Process: CNC Machining, CNC Lathe

3) Finish: Anodized, Electroplating, Sandblasting, Polishing

4) Tolerance: +/- 0.005mm

CNC Lathe parts

OTHER configuration:

Material: Aluminum, Copper, Stainless Steel

Dimensions:According to customer’s drawing.

Finish:Anodize,Sandblasting,Heat treatment,polishing,powder coasting,electroplating,spraying,

painting,silkscreen etc.

Tolerance:can reach to ±0.002mm

Quality control:100% inspected

Product

OEM/ODM Customized CNc Mechanical Hardware Fittings

1) Material: Aluminum, Copper, Stainless Steel Aluminum, Copper, Stainless Steel

2) Processing: CNC machining, CNC lathe.

3) Surface treatment: anodized, electroplated, sandblasted, polished.

4) Tolerance: +/-0.005mm +/-0.005mm

View More