Laparoscopic device-Medical Equipment Parts

OTHER configuration:

Laparoscopic device

1)Process: CNC lathe or machining center

2)Surface treatment: grinding, polishing

3)Material: stainless steel, titanium alloy

4)Processing difficulty: complex shape, small size, high precision requirement

Pedicle Screws

OTHER configuration:

Pedicle Screws

Material: Pedicle screws are usually made of titanium or stainless steel and are attached using materials such as carbon fiber

Design: Manufactured according to drawings

Functionality: Spine surgery, scoliosis correction and fracture treatment

Accuracy: Reduced complications

Medical equipment accessories

OTHER configuration:

Material: TC4

Process: Milling

Annual volume: 200PCS

Features: Four-axis machining

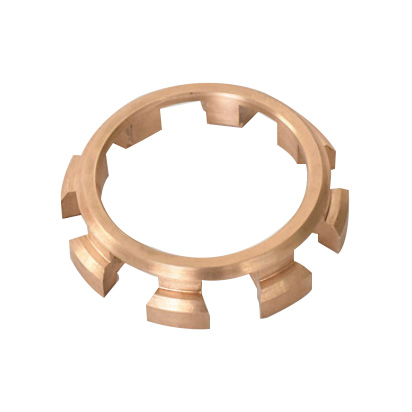

Straight Bevel Gear

OTHER configuration:

Material: C45,40Cr,20CrMnTi,42CrMo,Copper,Stainless steel

Size:Customer drawing

Colour:Natural

Finish: Hobbed

Surface Finish: Polished

cnc medical

Drive Gear

OTHER configuration:

Modulus: MI08

Number of teeth: unlimited

Pressure angle: 20°

Material: S45C etc.

Accuracy class: 5-6

Heat treatment: tempering, high frequency, nitriding

Drone body housing

OTHER configuration:

Material: Magnesium alloy

Size:According to customer’s drawing.

Finish: Anodised, sandblasted, heat treated, polished, powder coated, electroplated, painted

Tolerance:Can reach ±0.002mm

Quality control:100% inspection

Five-axis three-dimensional machining center aluminum plating parts

OTHER configuration:

OEM/ODM Customized CNC Machinery Parts for Hardware Part

1) Material: Aluminum, Copper, Stainless Steel

2) Process: CNC Machining, CNC Lathe

3) Finish: Anodized, Electroplating, Sandblasting, Polishing

4) Tolerance: +/- 0.005mm

frout lens cover

OTHER configuration:

Product Specific Purpose Audiovisual/projector

Color: transparency

Material: Glass

Controller: Type Push Button

Light Source: Type LED

Light Power: 5 Watts

Galvo scanner laser Accessories

OTHER configuration:

Single axis galvanometer Parameters:

1. Material: The metal spare parts on the laser oscillator are made of high quality stainless steel material.

2. Size: We can provide various sizes of metal spare parts according to customers’ requirements to meet their different needs.

3. Surface treatment: Our metal parts adopt various surface treatment technologies, such as sandblasting, anodizing, electroplating, etc., to improve their corrosion resistance and aesthetics.

4. Precision: Our metal parts and components can achieve high precision processing requirements with an error of ±0.01mm or less.

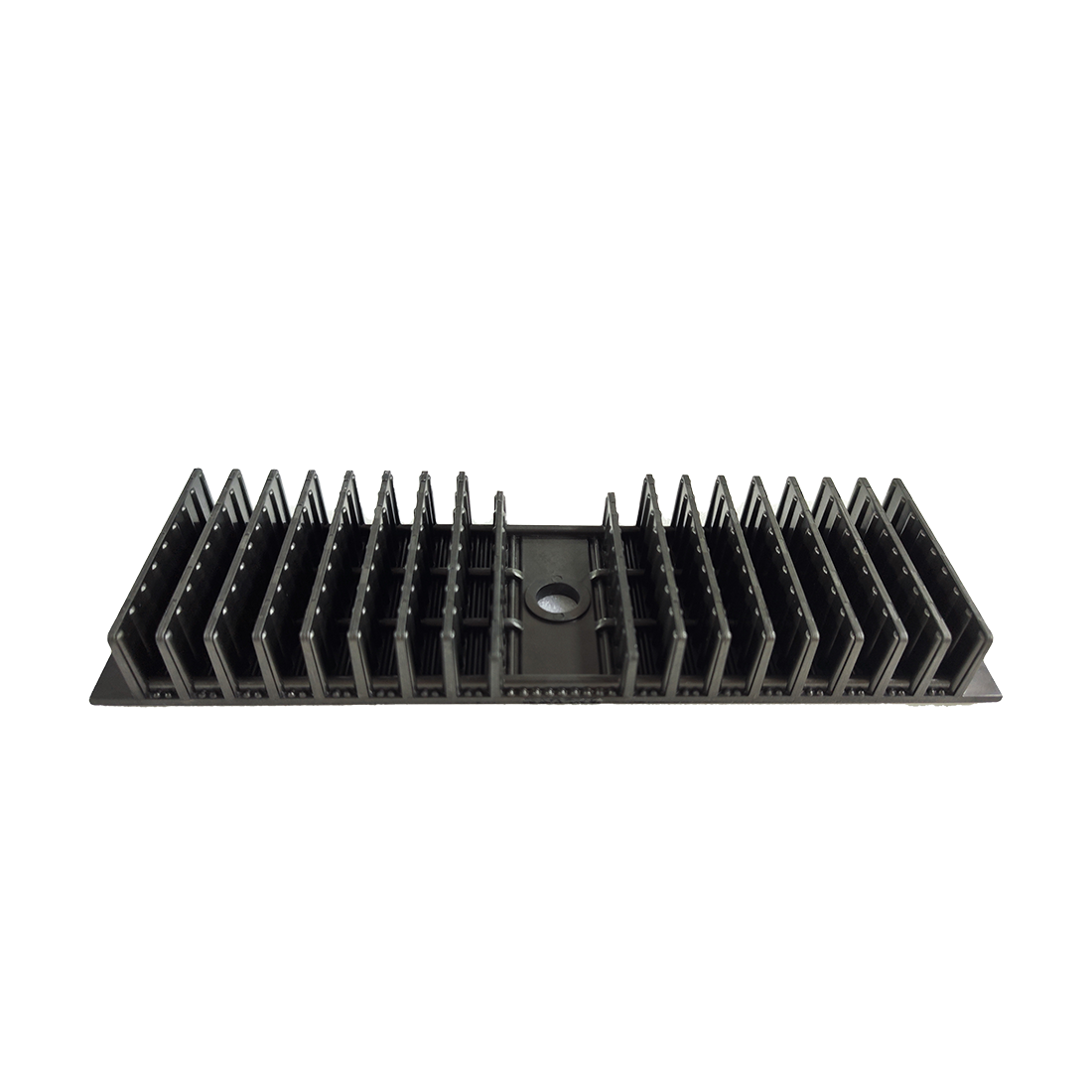

Graphene Heat Sink-LED lamp

OTHER configuration:

Raw Material: Graphene

Process: Injection moulding

Processing difficulty: flatness leveling

Surface treatment: polishing, deburring

Principal Client: Singyes New Materials

Heat Sink for Telecommunication, Powder Coat Finish

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

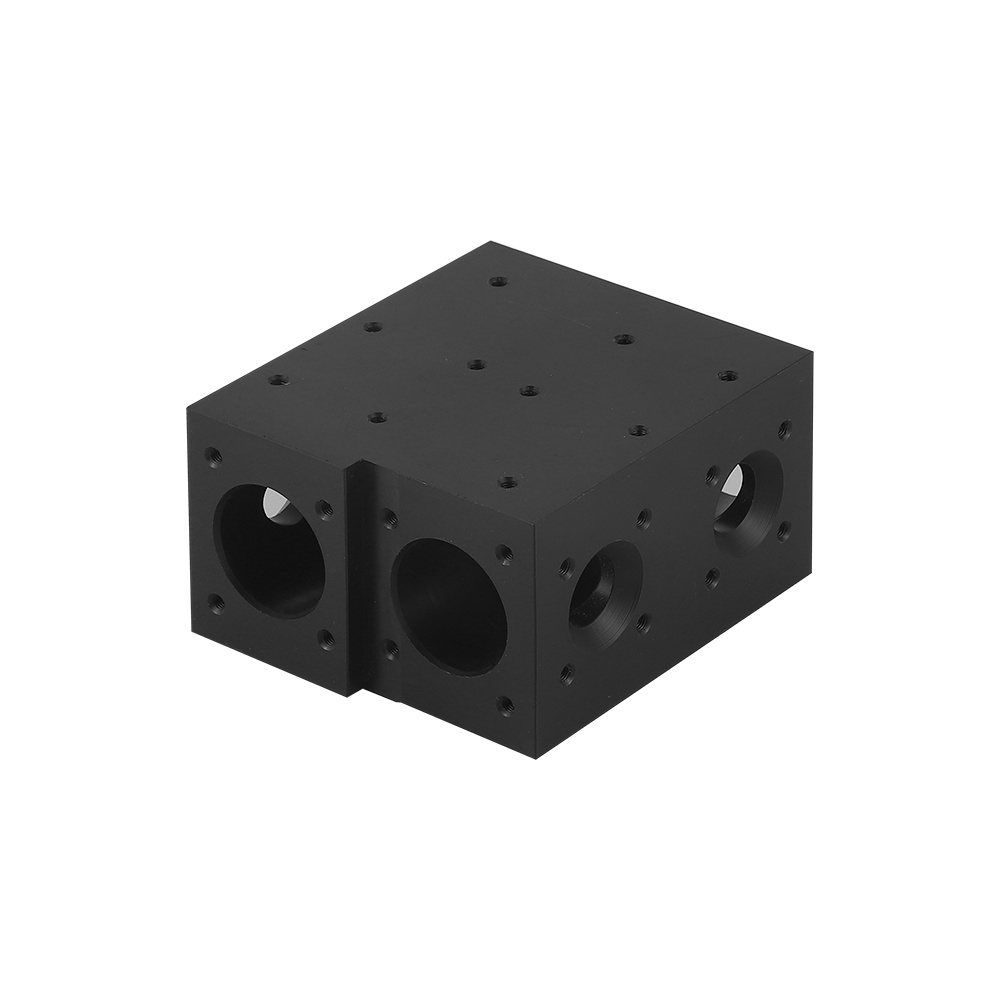

Hemodialysis equipment parts

OTHER configuration:

Material: 6061-T6

Process: Turning and milling

Surface finish: black anodized

Tolerance: ± 0.0005mm

Features: Rotary five-axis machining

High Precision Aluminum Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

High Precision CNC spindle tool holder ISO10

OTHER configuration:

Features:

Made of Japanese Daido SCM415 carburised steel with a core tensile strength of ≥950N/mm

Tool shank hardness of HRC54-56

Taper tolerance in accordance with AT3 grade, with a standard machine spindle fit surface of more than 90%

True roundness of internal and external taper ≤ 0.001mm, roughness ≤ Ra0.4

With cartridge and tool installed, tool runout is tested at ≤0.005mm when extended 5 times

Dynamic balance 100% inspection, meet 30000RPM, dynamic balance for G2.5

High Precision Stainless Steel Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

High Precision Stainless Steel Fixture, Jigs

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

Product

OEM/ODM Customized CNc Mechanical Hardware Fittings

1) Material: Aluminum, Copper, Stainless Steel Aluminum, Copper, Stainless Steel

2) Processing: CNC machining, CNC lathe.

3) Surface treatment: anodized, electroplated, sandblasted, polished.

4) Tolerance: +/-0.005mm +/-0.005mm

View More