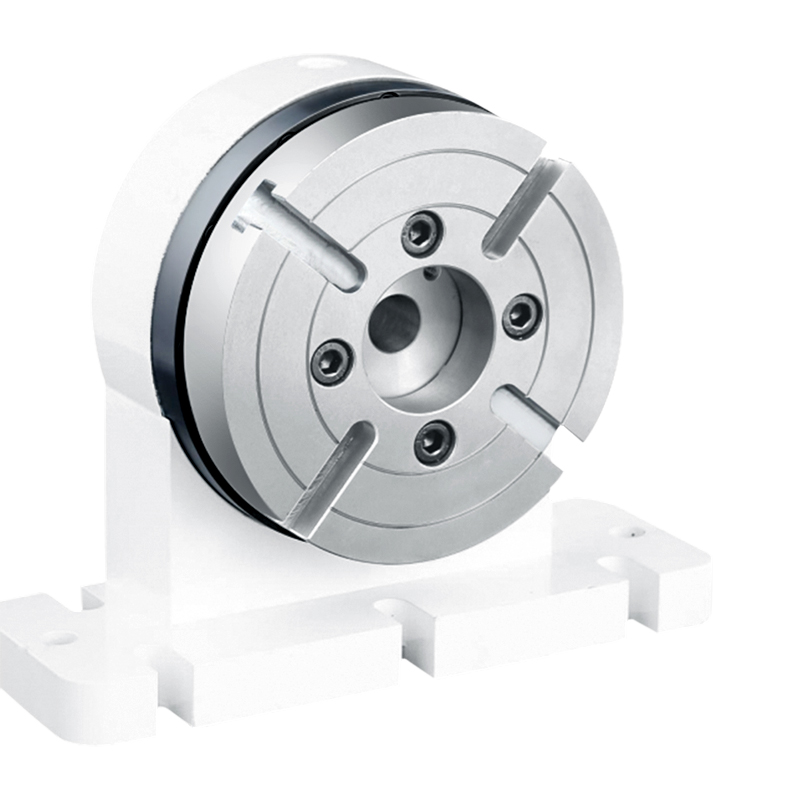

ROTARY TAILSTOCK SERIES

OTHER configuration:

Features:

1. Non-slip, stable and durable.

2. Protect the workpiece and increase the friction force

3. Fast loading and unloading of workpieces, saving time and effort

4. Improve processing and safety efficiency

· The main body is made of high quality alloy structural steel 42CrMo + open rough + tempered heat treatment process

· Spindle made of high quality steel from Great Wall Special Steel + heat treatment + grinding process

· Japan NSK double cone bearing, oil seal and other accessories are adopted

· Runout meets within 0.005mm

· Adopt air brake design, more sensitive, more stable

Rotor end caps-motors

OTHER configuration:

Material: Sumitomo PM9820 – Bakelite powder

Applications: motors, electromechanical products, etc.

Surface treatment: grinding, deburring

Process: Injection moulding

Scanning Handle, Black Anodize for Medical Equipment

OTHER configuration:

High Precision Customized Die Cating Part

1) Material: Aluminum Alloy: ADC12, A380, A360 Zinc Alloy: ZINC#3 ZINC#5

2) Process: Die Casting Process, CNC Machining Process

3) Finish: Powder Coating, Anodized, Oil Painting, Chroming ect.

4) Tolerance: +/- 0.1mm

Semiconductor equipment bases

OTHER configuration:

Material: SUS316

Process: Wire cutting, Milling ,Double side grinding, Lettering

Annual volume: 6000 PCS

Features: 0.5 small cutter processing, intersection hole burr not easy to remove

Semiconductor equipment connectors

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

Semiconductor equipment connectors

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

Semiconductor equipment parts

OTHER configuration:

Material: SUS304

Process: Milling -Surface grinding

Annual volume: 1000-2000PCS

Processing difficulties: flatness 0.01, cross hole burr removal

Semiconductor equipment platens

OTHER configuration:

Material: SUS304

Process: milling – grinding and polishing

Annual volume: 2000-3000PCS

Processing difficulties: thin structure of the workpiece is easy to deformation, parallelism 0.01

Semiconductor equipment support frame

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

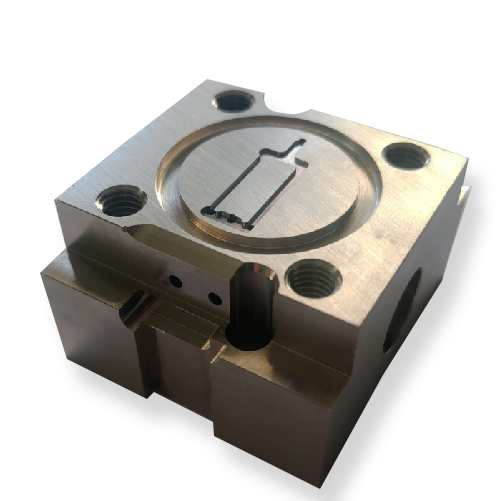

Semiconductor valve block

OTHER configuration:

Material: 6061-T6

Process: Milling – Anodizing – Deburring – Laser engraving

Annual volume: 500-1000PCS

Features: Tolerance 0.006mm

Processing difficulties: Through-hole burrs are not easy to remove

Shaft parts for Petroleum Machine

OTHER configuration:

Material: Aluminum, Copper, Stainless Steel

Dimensions:According to customer’s drawing.

Finish:Anodize,Sandblasting,Heat treatment,polishing,powder coasting,electroplating,spraying,

painting,silkscreen etc.

Tolerance:can reach to ±0.002mm

Quality control:100% inspected

Product

OEM/ODM Customized CNc Mechanical Hardware Fittings

1) Material: Aluminum, Copper, Stainless Steel Aluminum, Copper, Stainless Steel

2) Processing: CNC machining, CNC lathe.

3) Surface treatment: anodized, electroplated, sandblasted, polished.

4) Tolerance: +/-0.005mm +/-0.005mm

View More